FAQ.This is brand new, breakthrough technology that we are introducing to the world of beekeeping. Answers to common questions about the machine are below.

|

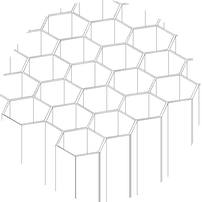

What does the machine do?BREAT has created a machine which makes nature beeswax honeycombs, ready to put in the frame, that mimic those made by bees.

|

Why did we invent this machine?Presently, There has been talk for years about issues such as increasing honey yield, limiting the use of pesticides and drugs, and other significat problems facing the industry.

We saw the need. and the actualized the possibility, of bringing our engineering expertise to bear to solving this problem while greatly reducing difficulties that modern beekeepers face. |

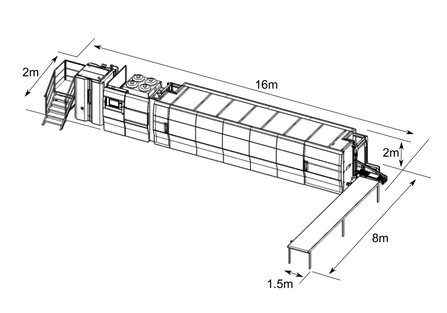

What is the size of machine?The overall dimensions of the installed machine are: LENGTH, 16m (52.49ft); WIDTH, 8m (26.24 ft); HEIGHT 2.2m (7.2 ft).

The central part of machine where the honeycombs are produced is 11.7m (38.38ft) of long by 2.1m (6.88ft) width and 2.2m (7.21ft) high. Its design allows for it to very easily transported and installed. |

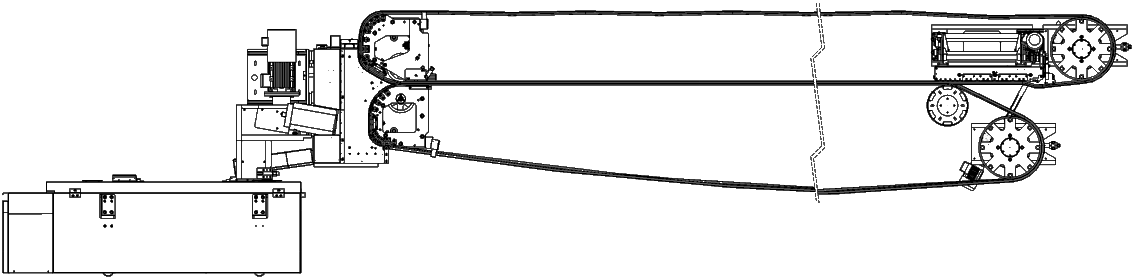

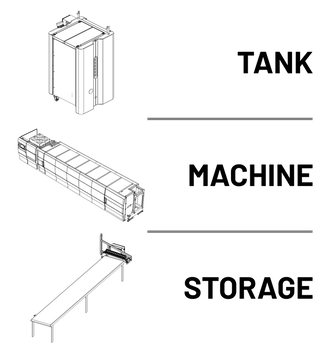

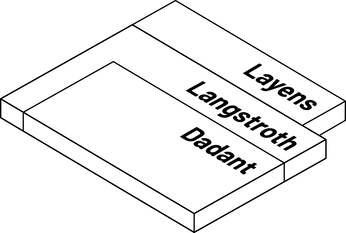

How is the machine configured?The machine consists of three sections, allowing for best adaptation to the client's requirements. The sections are:

1. Liquidation and filtering tank 2. Production machine 3. Storage on conveyor belt The most important elements is the central part (production machine) which makes the honeycomb. The other two are peripheral elements and can be adapted for the buyer's need. |

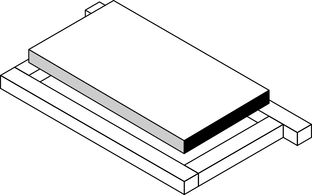

How does the machine work?The production process for this automated machine is as follows: natural beeswax is placed in the tank, where it is heated and liquefied; it is first filtered and then injected into a continuous silicone mold; the wax is cooled as it travels down the tunnel; when cool, the honeycomb is extracted from the mold, then cut and stacked.

The wax processing is totally clean, without the use of any chemicals or additives. |

Is it registered? |